THE TRIBOLOGICAL BEHAVIOR OF WOOD AND STEEL

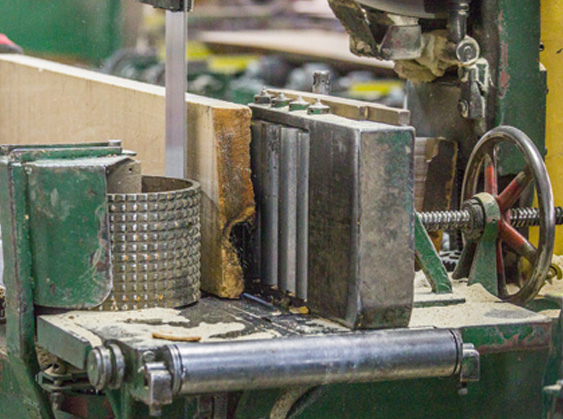

If you’ve ever wondered what the best surface technology for steel in the wood processing environment would be, then you’ve come to the right place.

The tribological behavior of wood and steel has been a subject of interest for many researchers, engineers, and enthusiasts. In this blog, we will take a closer look at the tribological behavior of wood and steel, exploring how these two materials behave when they come into contact and what factors influence their performance.

The tribological behavior of wood and steel depends on the specific conditions in which they interact and the properties of the materials.

In general, wood is a softer and less dense material than steel, and its coefficient of friction is lower. This means that wood tends to wear out more quickly than steel when the two materials come into contact with each other, and it can also experience more sliding or slipping. The type and condition of the wood, as well as the presence of contaminants or moisture, can also affect the tribological behavior of wood.

In certain applications, such as woodworking or construction, it may be necessary to reduce friction or wear between wood and steel. This can be achieved through the application of surface coatings such as chrome plating or laser cladding. Some of the key properties to look for include:

- Corrosion resistance: Woodworking environments can expose steel components to moisture, which can cause corrosion. A coating with high corrosion resistance is important to prevent rust and degradation of the steel.

- Durability: Woodworking equipment and components can undergo wear, which is why a coating with good durability is essential to ensure long-lasting protection.

- Chemical resistance: Woodworking involves the use of adhesives, finishes, and other chemicals that can damage steel. A coating resistant to these chemicals can help prolong the lifespan of steel components.

- Adhesion: The coating must adhere well to the steel substrate to provide effective protection. Poor adhesion can lead to premature coating failure.

- Aesthetic appeal: In some cases, the appearance of the coating may be important for aesthetic reasons. A coating with a smooth and attractive finish can enhance the overall appearance of woodworking equipment and components.

CONTACT INFORMATION

2735 Rue Jules Vachon

Trois-Rivières (QC) G9A 5E1

T : 1-877-807-2739