CORROSION PHENOMENA

Corrosion, that insidious phenomenon that silently eats away at materials, is one of the major challenges facing many industrial sectors today..

Corrosion is the process by which a material, typically a metal, degrades and deteriorates due to chemical reactions with its environment. There are several types of corrosion that can occur, depending on the specific chemical reactions and environmental conditions.

Some common types of corrosion include:

- Uniform corrosion: This is the most common type of corrosion, in which the surface of the material is uniformly attacked by the corrosive agent. It results in the loss of material from the surface, and it can occur over the entire surface or in specific areas, depending on the environment and the material’s properties.

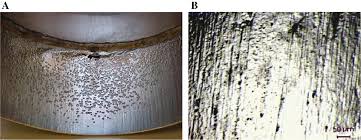

- Pitting corrosion: This type of corrosion occurs when small, deep pits or holes form on the surface of the material. It is often caused by the presence of a corrosive agent that concentrates in specific areas, such as at the edges of a material or in cracks or crevices.

- Crevice corrosion: This type of corrosion occurs when the corrosive agent is confined to small crevices or gaps on the surface of the material. It can be caused by the presence of dirt, dust, or other contaminants that trap the corrosive agent in a small area.

- Galvanic corrosion: This type of corrosion occurs when two different metals are in contact with each other in the presence of an electrolyte. One of the metals becomes the anode, and it corrodes more rapidly than the other metal, which becomes the cathode.

- Intergranular corrosion: This type of corrosion occurs at the grain boundaries of a material and is often caused by the presence of impurities or defects in the material.

- Erosion corrosion: This type of corrosion occurs when the surface of the material is mechanically abraded or worn away by the flow of a corrosive liquid or gas. It is often found in piping systems and other components that are exposed to high-velocity fluids.

- Stress corrosion cracking: This type of corrosion occurs when a material is subjected to both tensile stress and a corrosive environment. It can lead to the formation of cracks on the surface of the material, which can eventually lead to failure.

.

- Corrosion fatigue: This type of corrosion occurs when a material is subjected to alternating loads or cyclic stresses in a corrosive environment. It can lead to the formation of cracks and eventual failure of the material.

Corrosion is a major problem for many industries as it is costly to maintain metals. There are different methods been used such as painting, coating and galvanizing. We will describe the impact of using laser cladding or chrome plating protection in future articles.

CONTACT INFORMATION

2735 Rue Jules Vachon

Trois-Rivières (QC) G9A 5E1

T : 1-877-807-2739